Project information

- Category: Engineering

- Tools: Yokogawa DCS Centum VP

- Advisor: Dr.-Ing. Awang Noor Indra Wardana, S.T., M.T., M.Sc.

DCS Yokogawa Centum VP case Knock-out Drum on Flare System

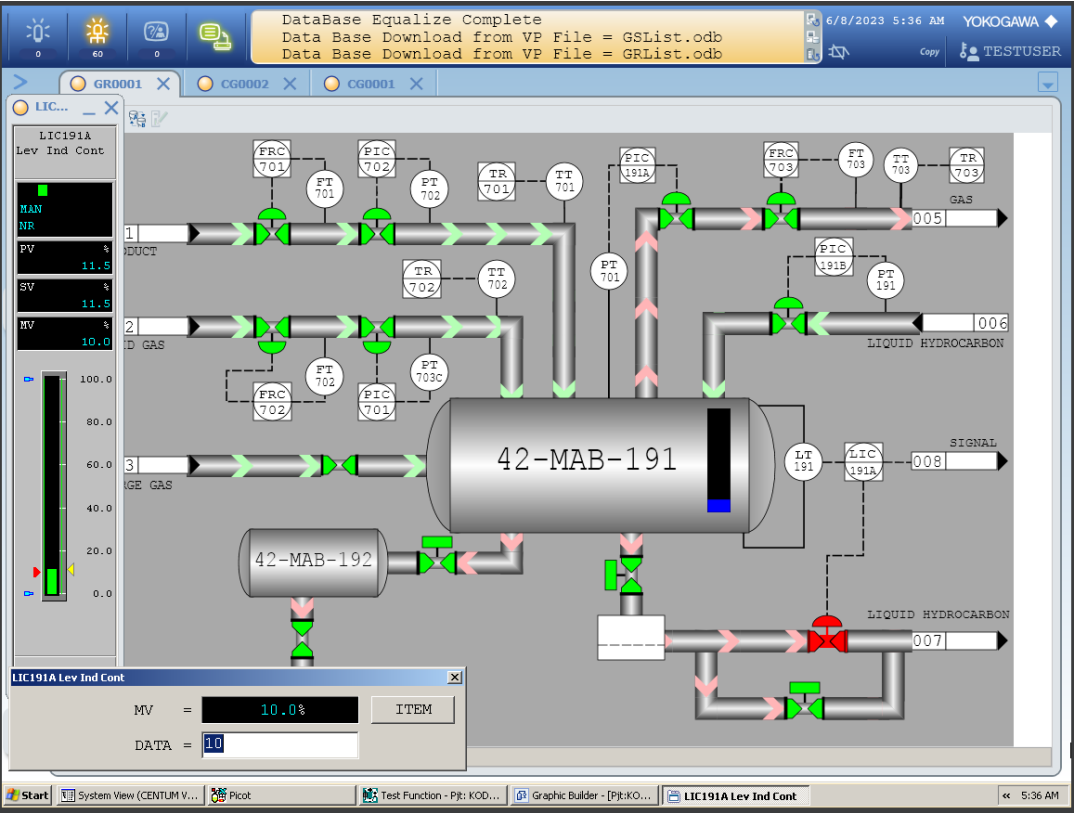

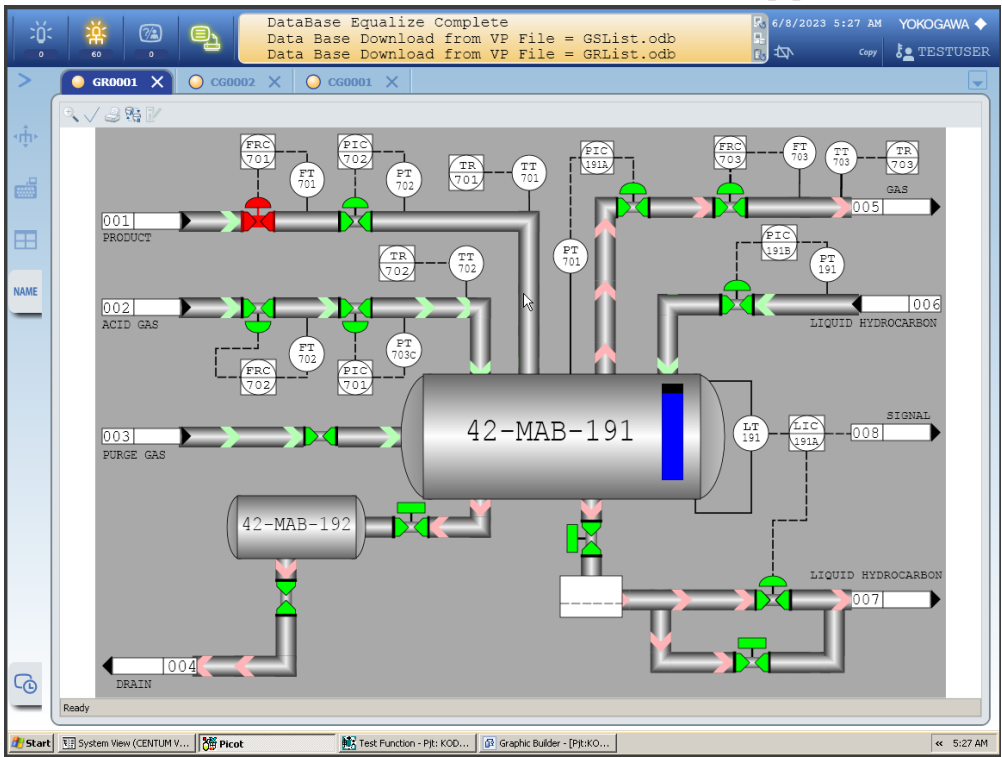

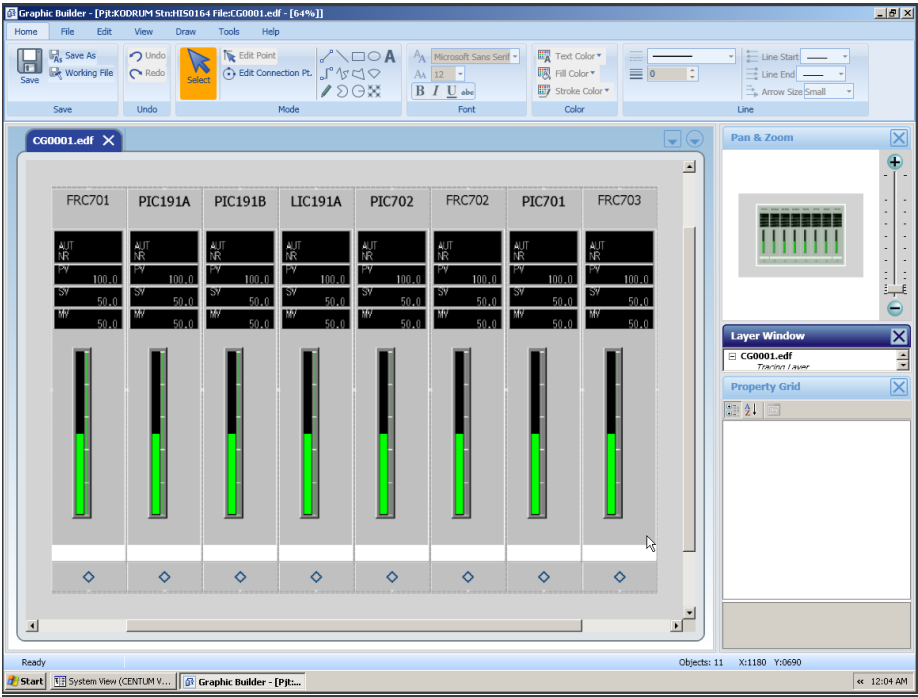

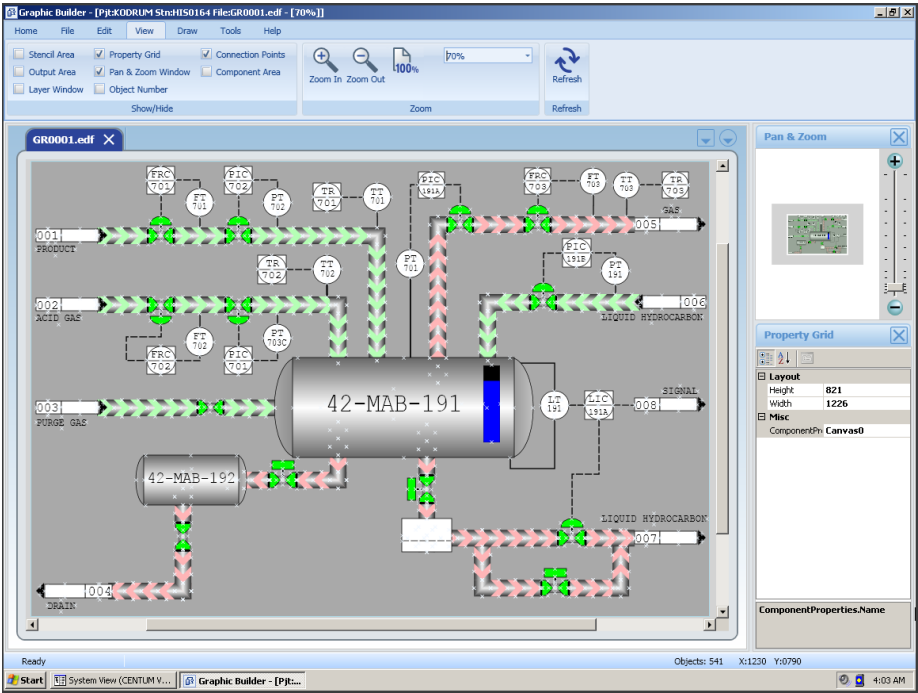

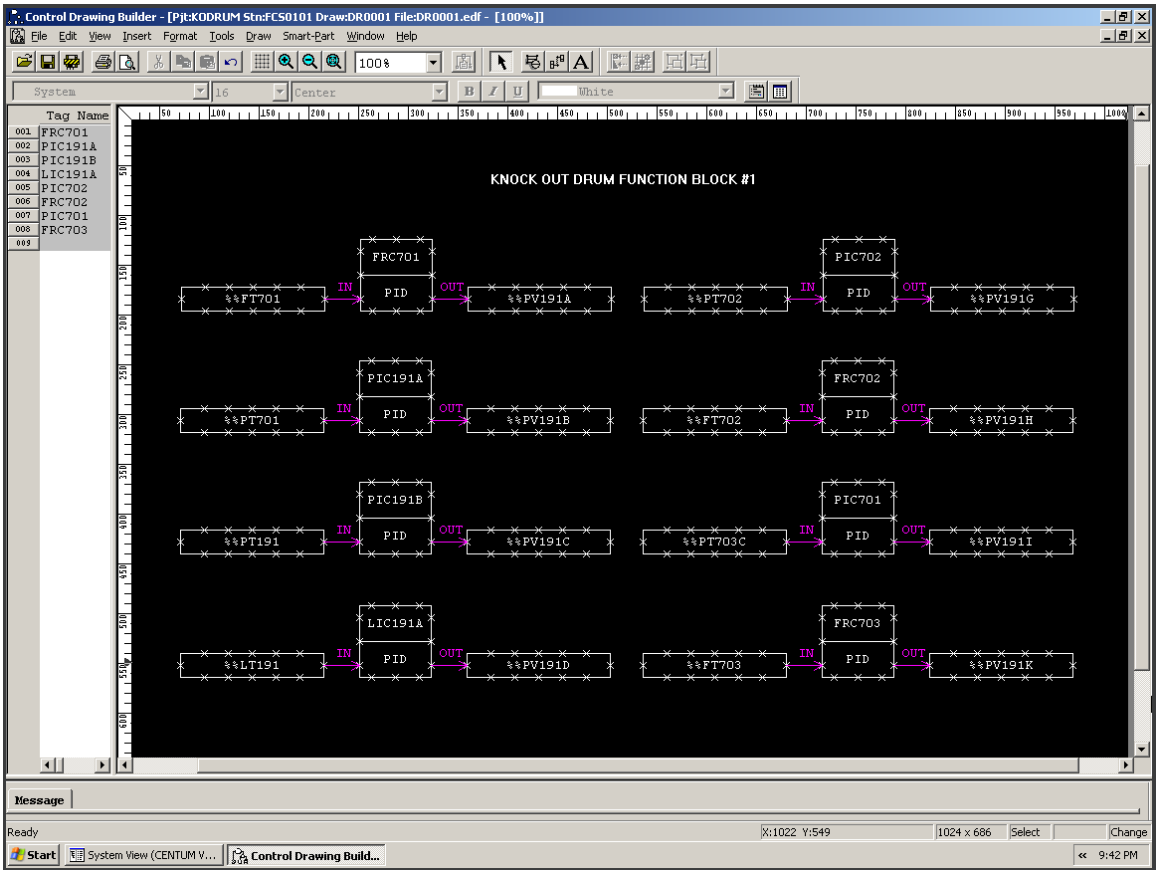

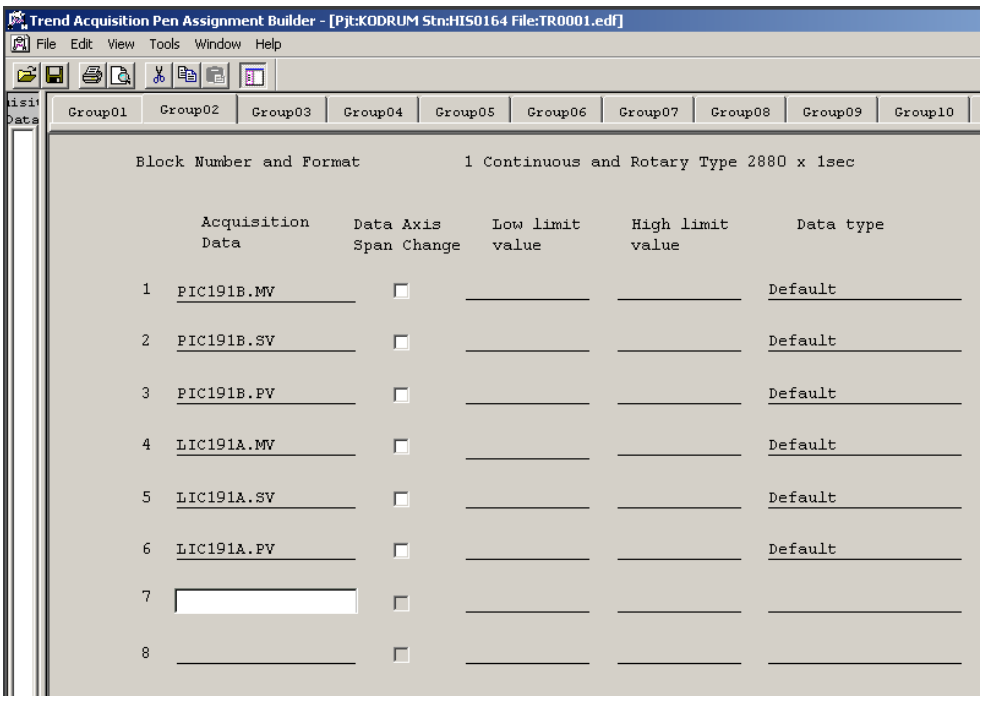

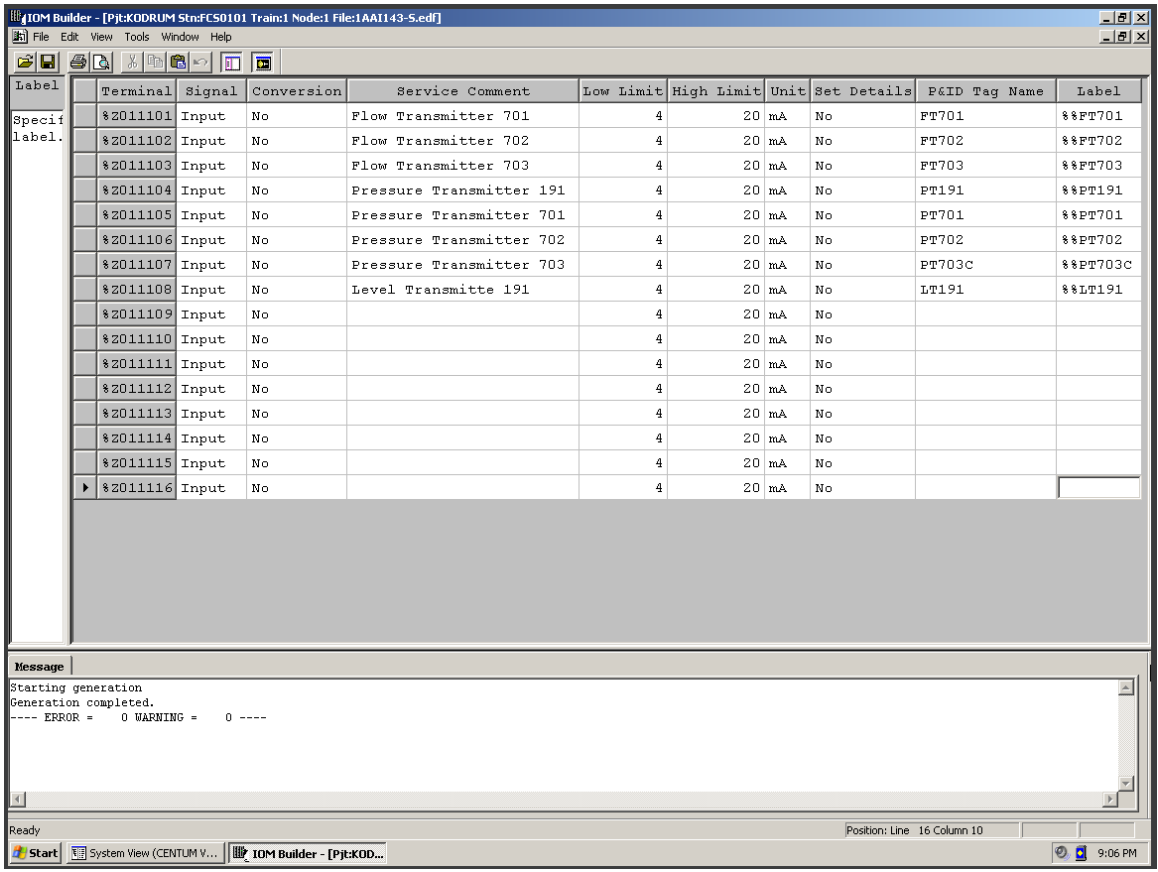

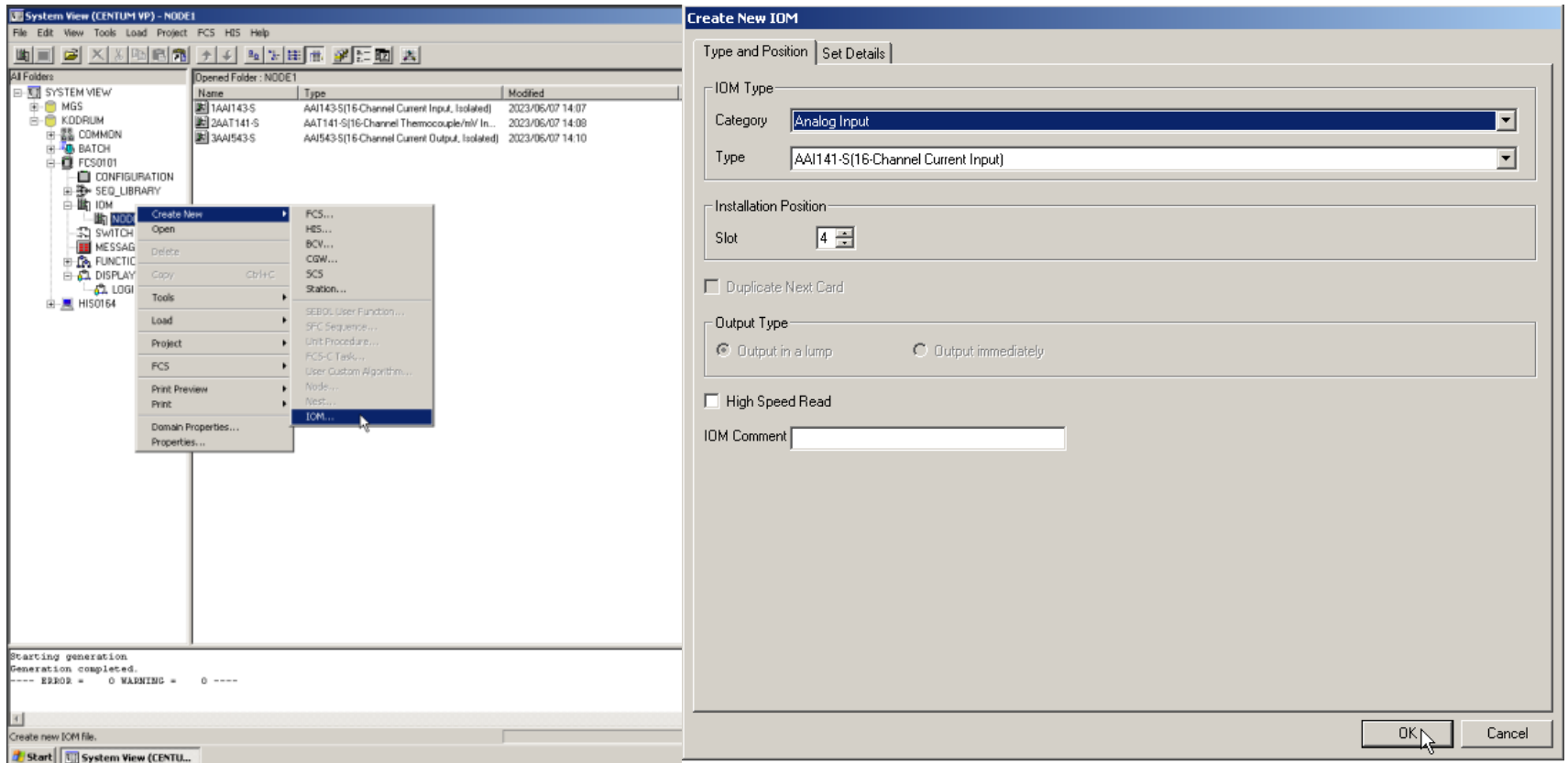

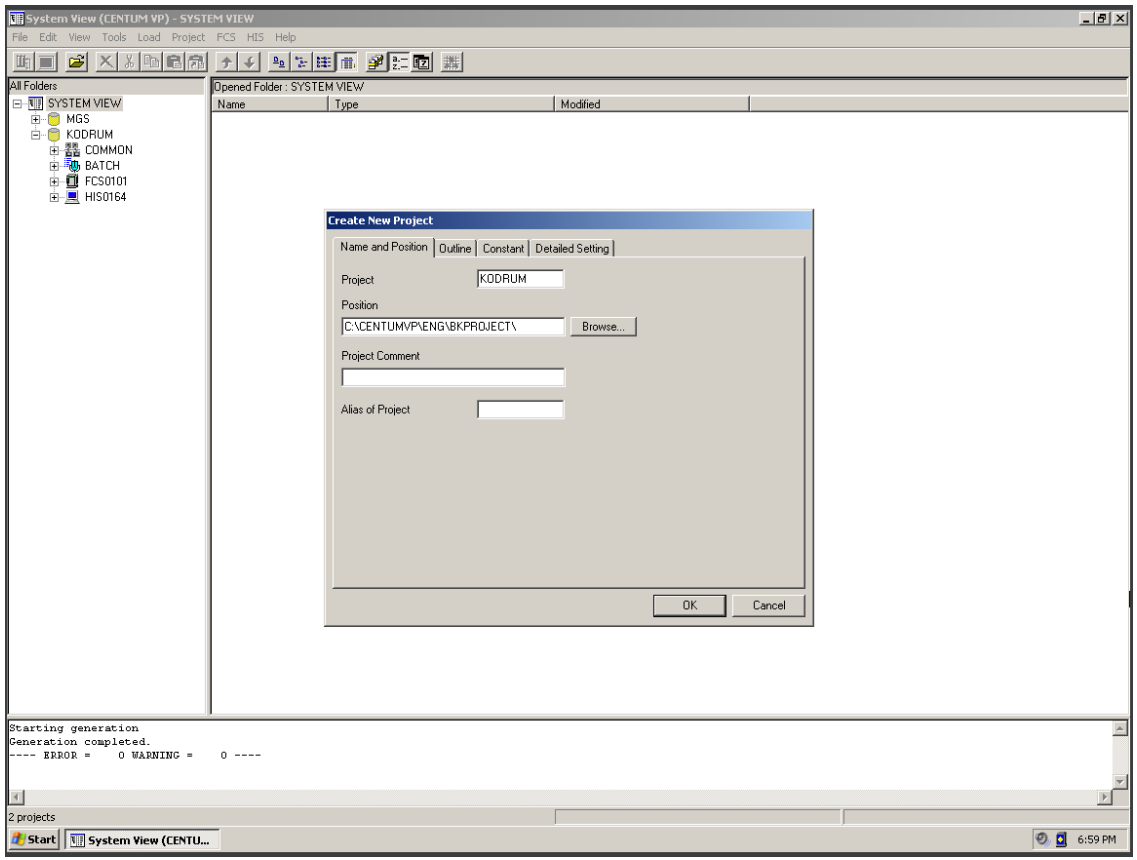

Designing an automation system for Knock-out Drum in Flare System using DCS Yokogawa Centum VP. I designed and implemented this system using the Engineering Station software in Yokogawa Centum VP. The process started with creating a new project, defining the FCS and HIS, and specifying the required Input/Output nodes and modules. The tools used were FCS type AFV10D Duplexed Field Control Unit for Vnet/IP and HIS type PC with Operation and Monitoring Functions.

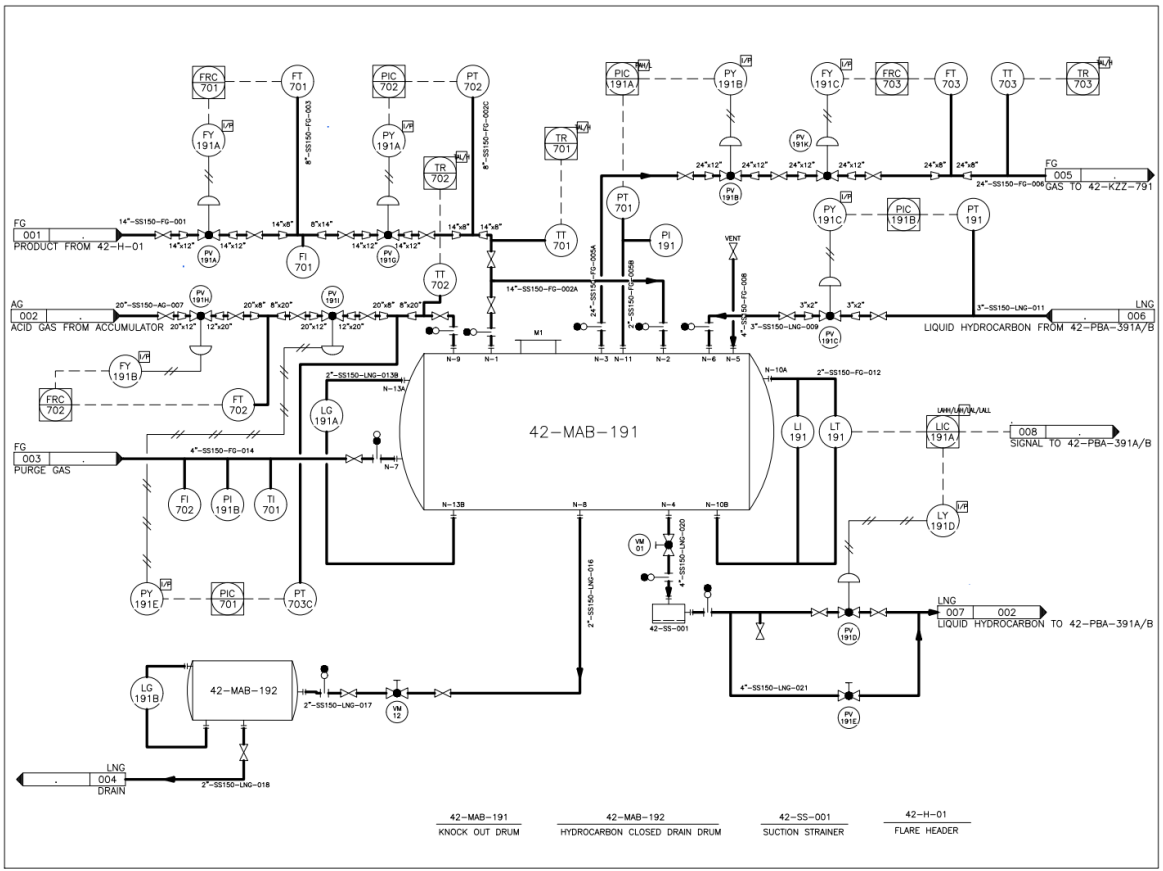

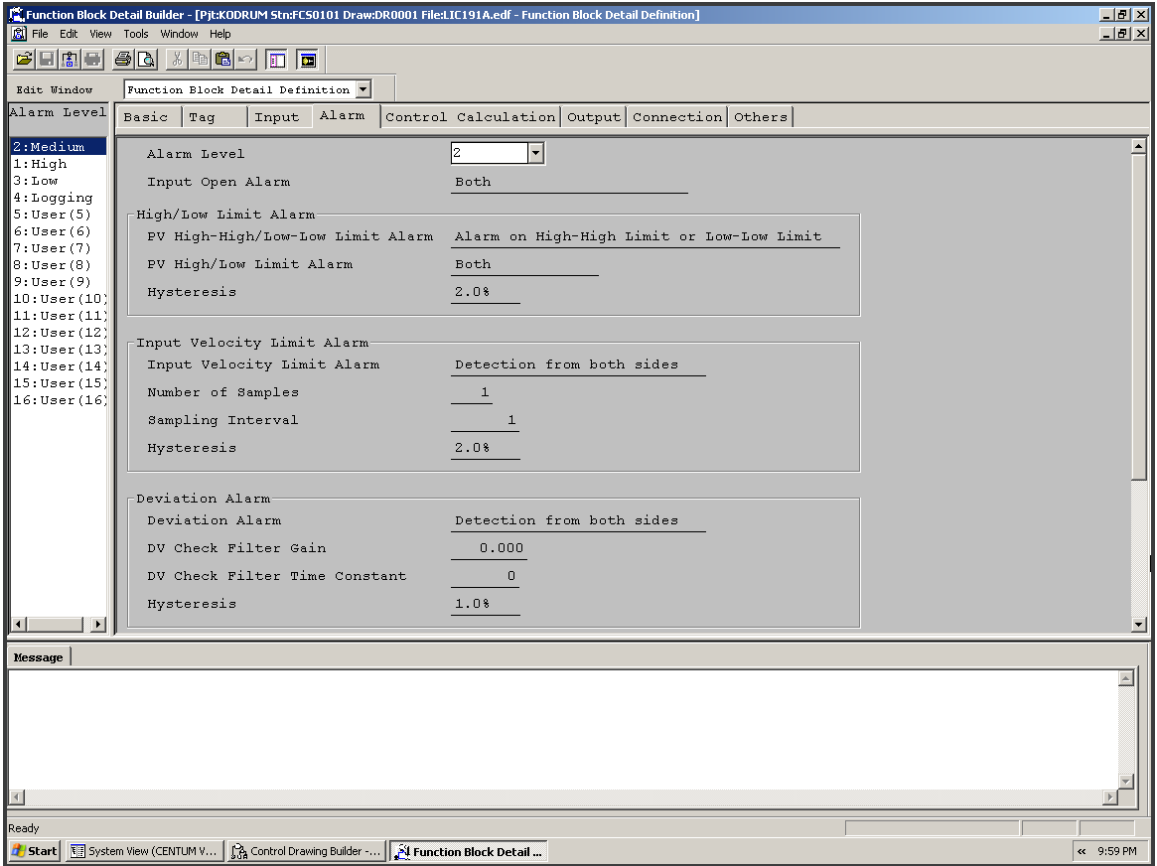

The P&ID analysis shows the various instruments that go into the DCS, such as the PIC, FRC, LIC, and TR, which will control the final elements such as the PV control valves. The DCS processing process involves signal conversion to control the final element through the control valve. Next, they created the DCS architecture and set up the control functions using the Control Drawing Builder. They also configured the HIS for operation and monitoring, and created graphical visualizations of the process flow.

Simulations were performed using the Virtual Test Function (VTF) in Yokogawa CENTUM VP, enabling offline testing and validation of control logic without interrupting real operations. In conclusion, this project successfully created the architecture of the Knock-out Drum P&ID of the Flare System with all the necessary design and simulation steps using Yokogawa Centum VP DCS.